Clear visibility promotes new discovery

Clear visibility promotes new discovery

Nowadays, not only resolution and analytical performance on the nanometer order, but also throughput in data acquisition are considered important. The newly born JSM-IT710HR is the fourth-generation model of JEOL's HR* series, which is based on the theme of "SEM that allows anyone to easily take high-resolution images.

The JSM-IT710HR makes users want to pursue beyond what has been seen, due to ease of operation with enhanced automatic functions and improved observation performance from a new detector.

*HR=High Resolution

Features

I can see it, I want to see it more.

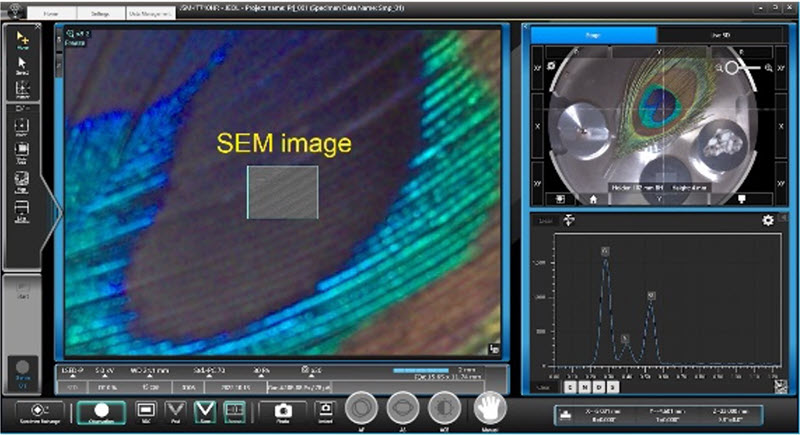

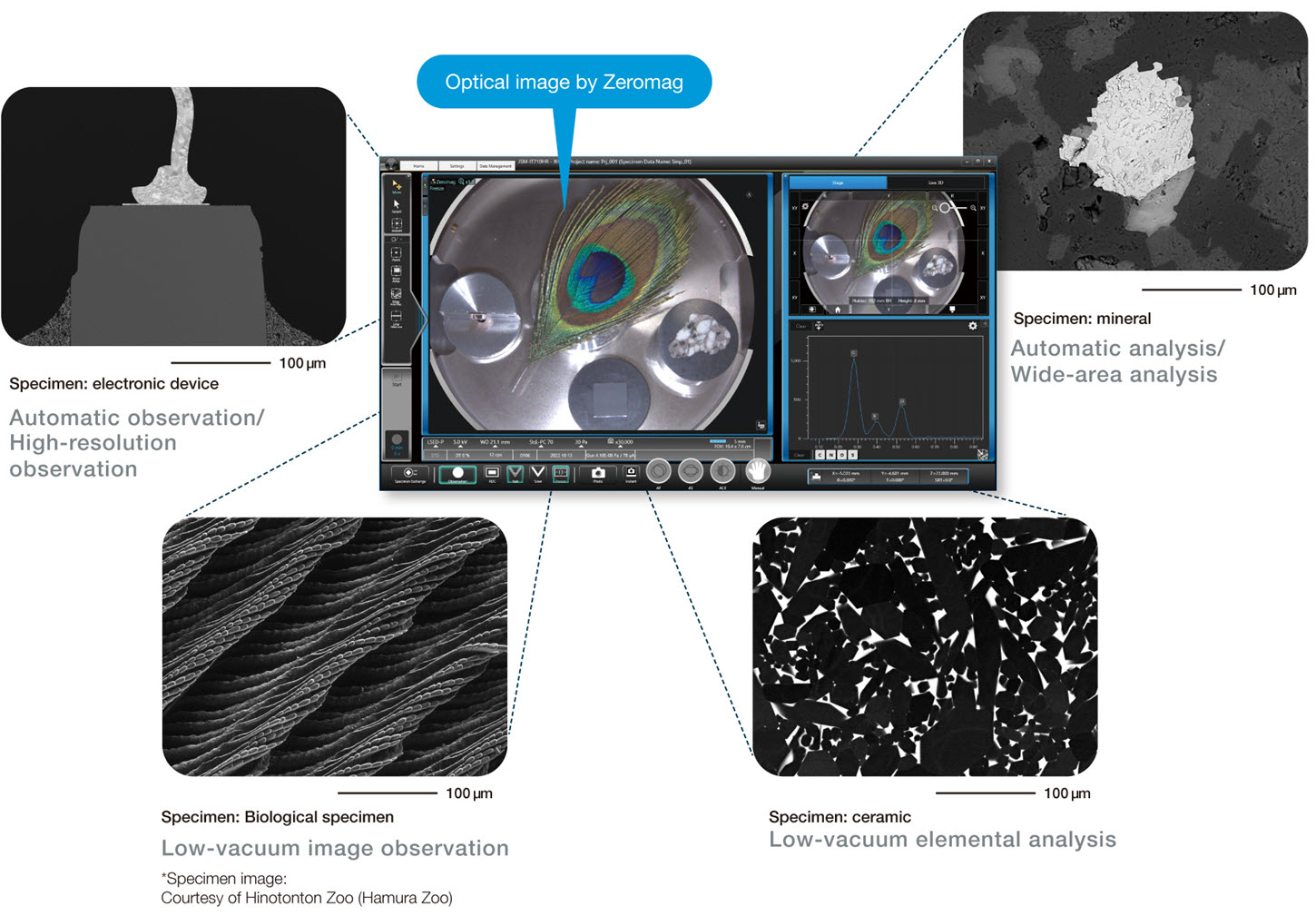

| The SEM image is visible in conjunction with the optical image. |

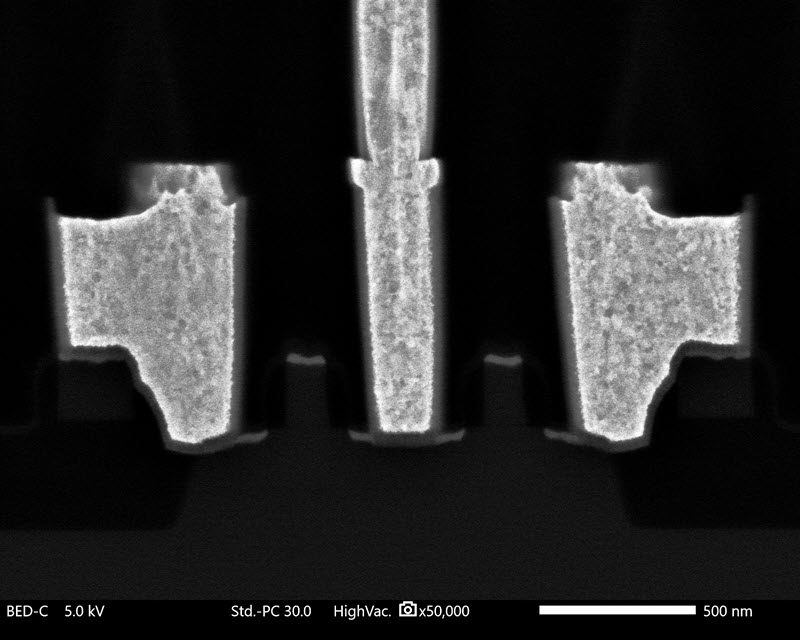

The image is seen better due to the high resolution electron gun. |

|

Specimen: courtesy of Hino Tonton ZOO (Hamura Zoo)

|

|

※optional

Charge reduction

Specimen: Courtesy of Prof. Tetsuro Asakura, Department of Biotechnology and Life Science, Tokyo University of Agriculture and Technology

Crystal structure analysis

Specimen: Courtesy of Prof. Kaneaki Tsuzaki, National Institute for Material Science (NIMS)

New functionality

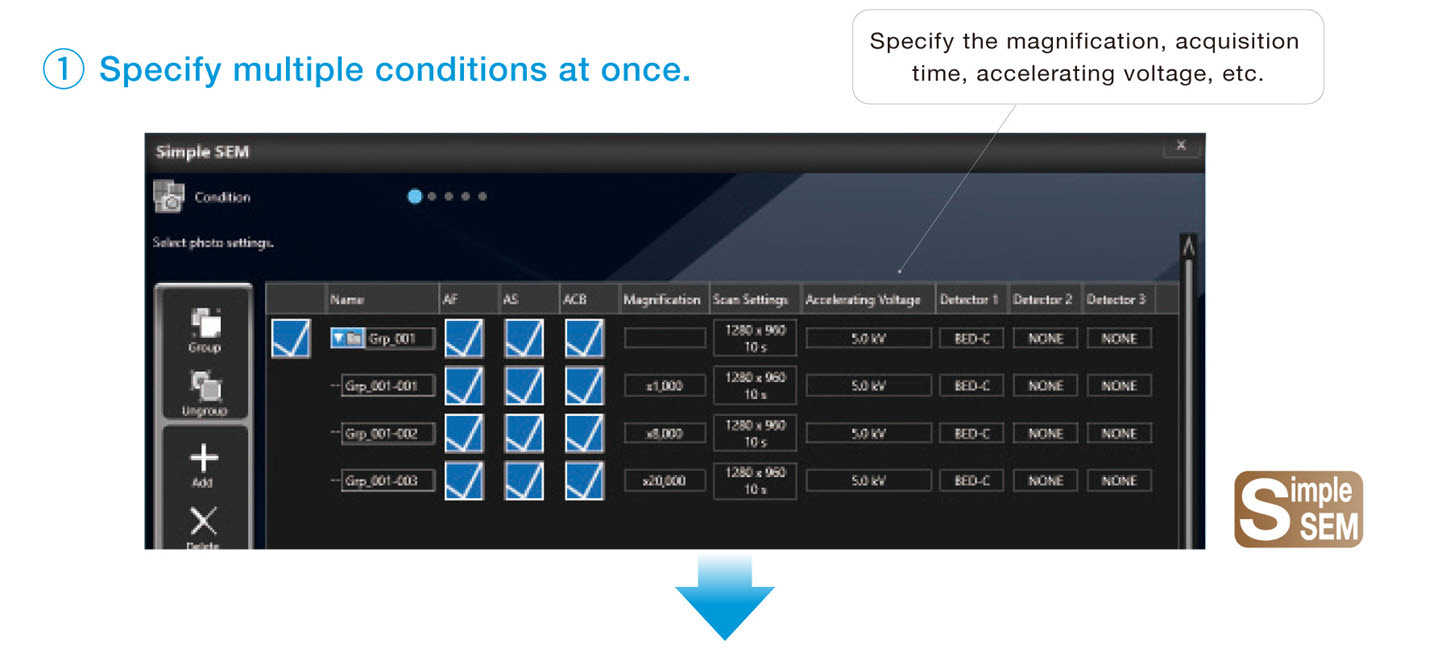

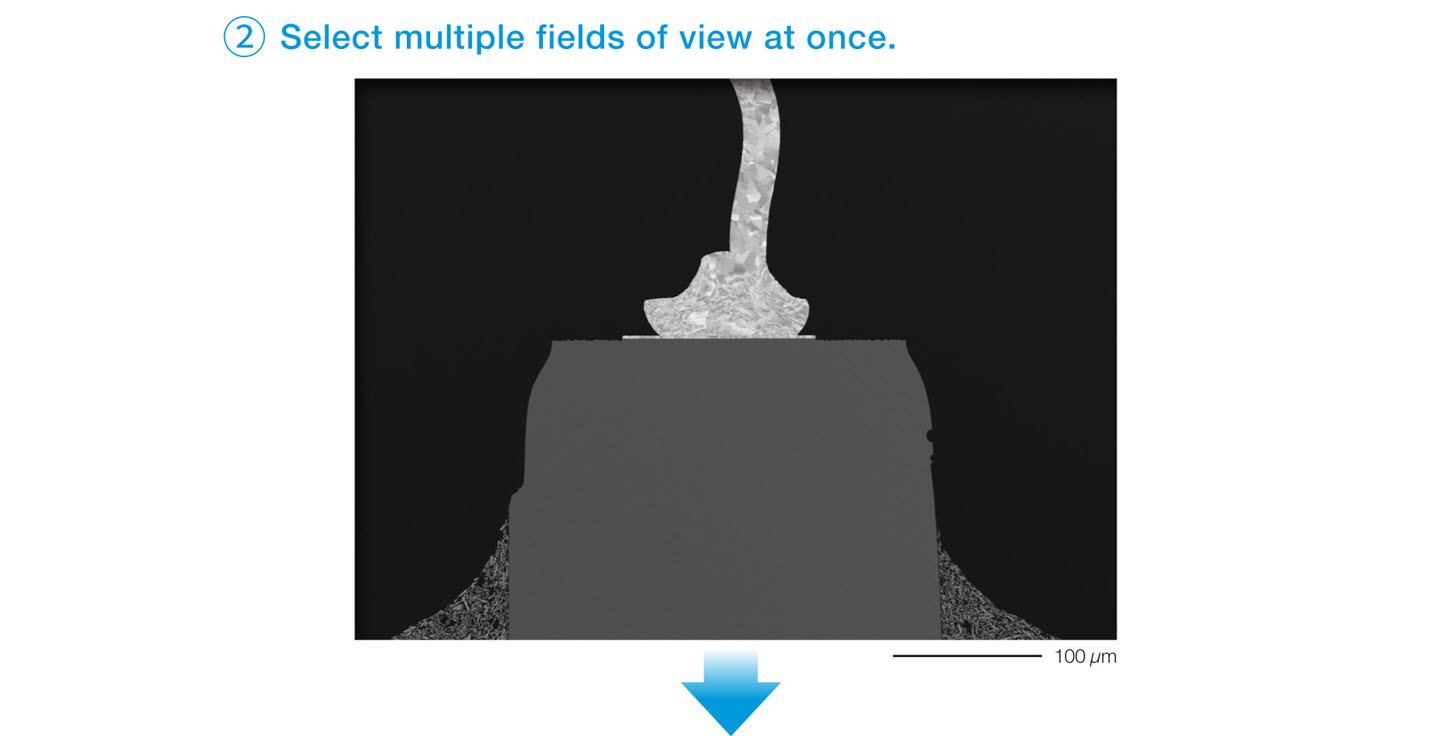

Automatic Observation: Simple SEM/EDS

Simple SEM function enables automatic measurements by registering multiple conditions at once. Simple

This improves the efficiency of routine work.

Live 3D: constructs 3D image on the spot

Imaging is possible at a low magnification with a little distortion, due to the out-lens objective lens.

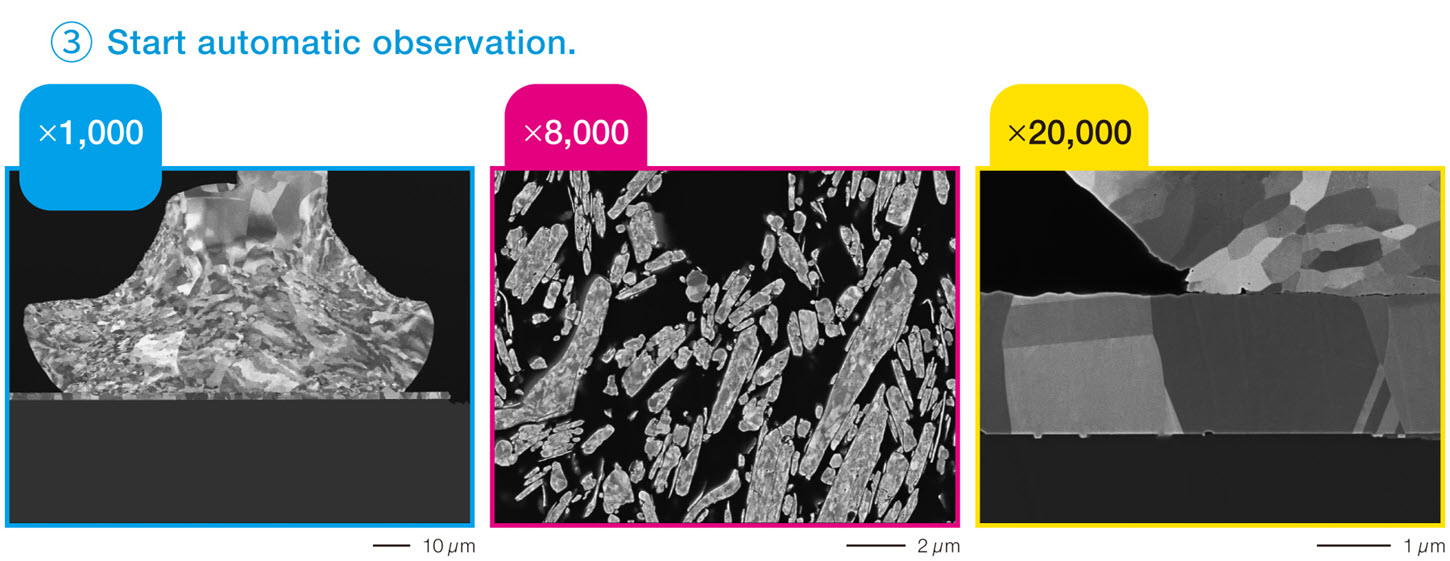

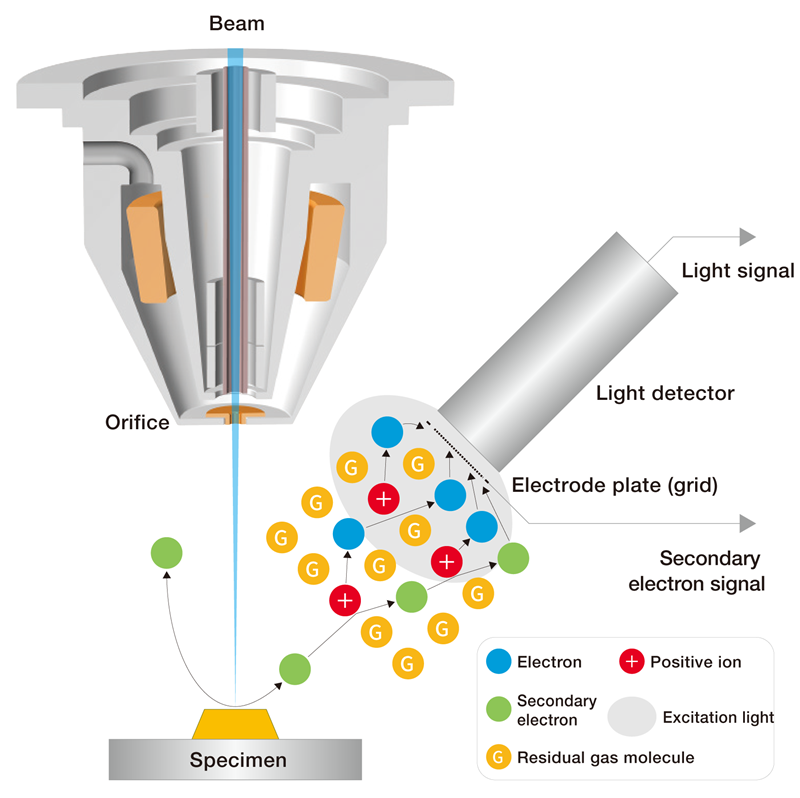

New Low Vacuum Hybrid Secondary Electron Detector (LHSE)※

※Optional function

The LHSED, a new low-vacuum detector, enables observation while switching between images containing light emission information and topographic images.

|

LHSED Features

- Improved quality of low vacuum secondary electron live image

- Acquisition of light emission information

- Switching between topographic and light emission information images

|

|

Schottky FE electron gun stability has been enhanced more than 4 times compared to the previous models

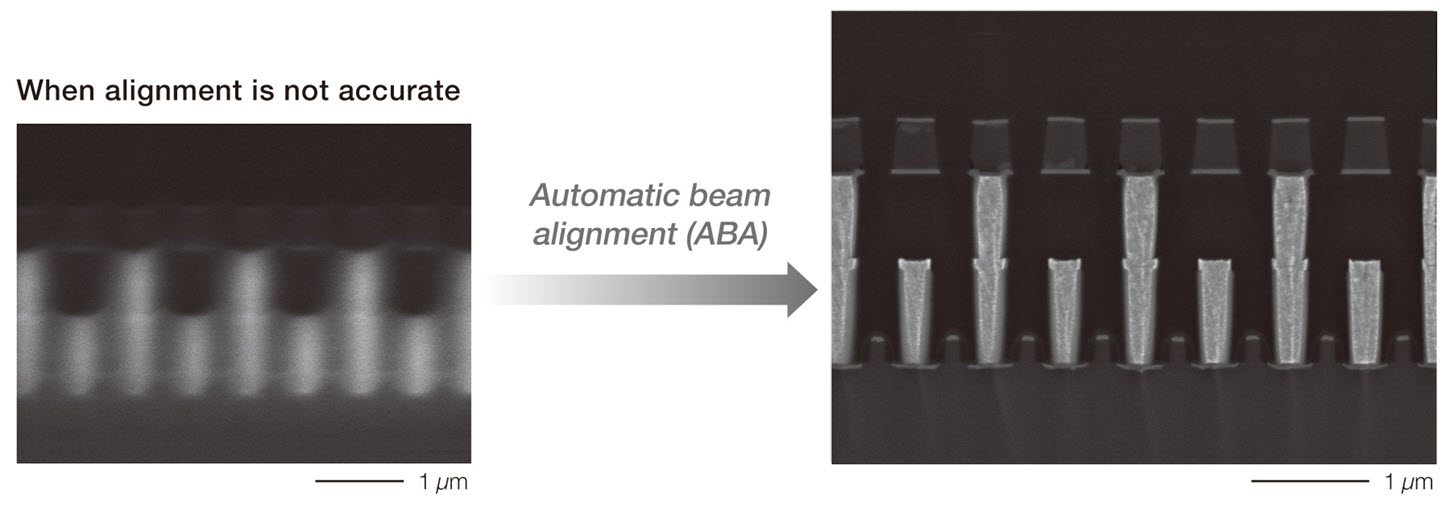

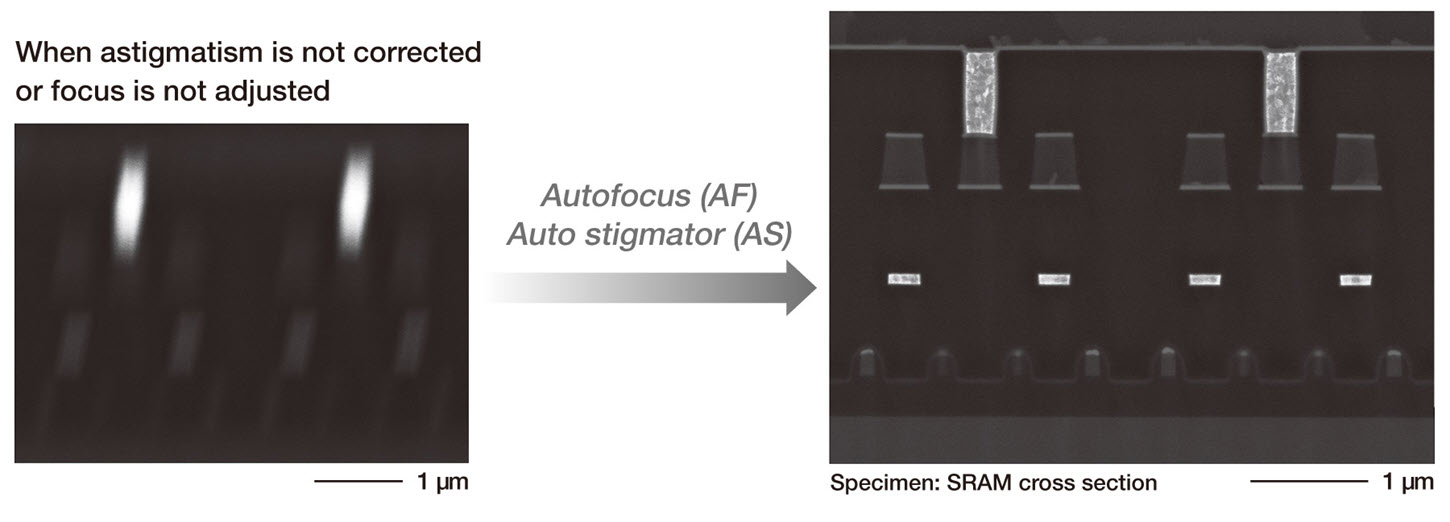

Automatic Beam Adjustment

JSM-IT710HR does not require complicated manual adjustment and provides automatic adjustment from axis alignment to astigmatism correction and focusing.

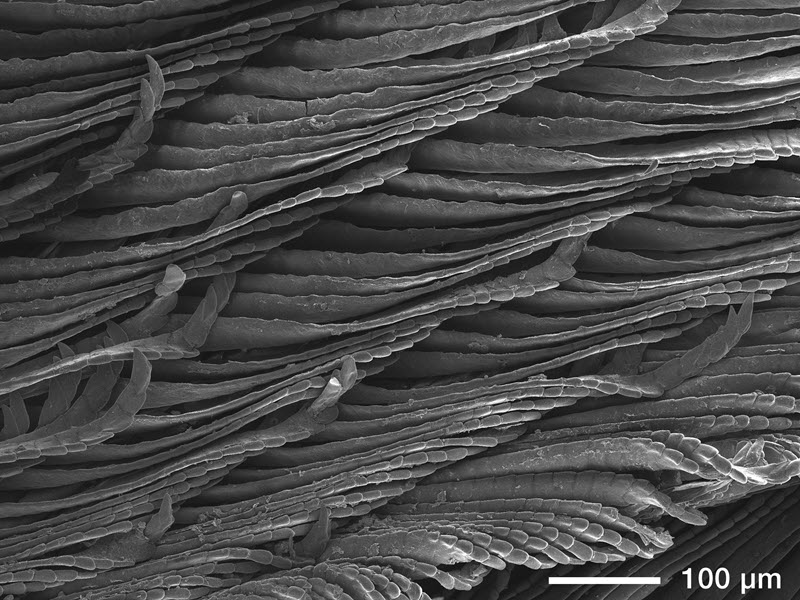

Secondary Electron Detection System

Secondary electron detector

(SED) |

Low vacuum secondary electron detector

(LVSED/LHSED) |

Specimen: Feather of peacock*

*Specimen image: Courtesy of Hinotonton Zoo (Hamura Zoo) |

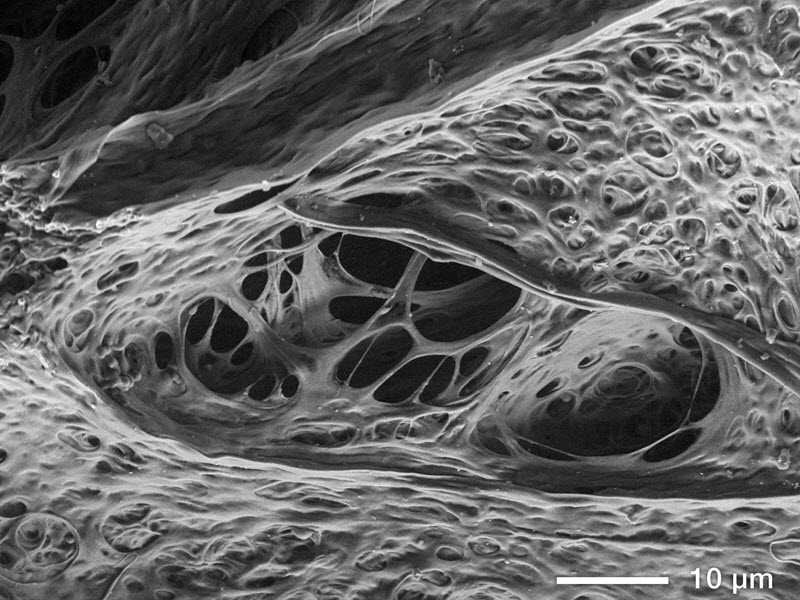

Specimen: cellulose microfiber |

Both High Resolution and Large Current

The Schottky field emission gun used in the JSM-IT710HR enables high-resolution observation and analysis because the electron gun is integrated with the condenser lens to create large currents while maintaining a small probe.

Backscattered Electron Detection System

The new multi-segmented backscattered electron detector acquires backscattered electron images from four directions at once so that a simple 3D image can be created and displayed live, in real-time.

Every Analysis Starts with Zeromag

Zeromag's optical image simplifies navigation.

SEM images can be linked to optical images for easy observation, analysis, and automated measurements.

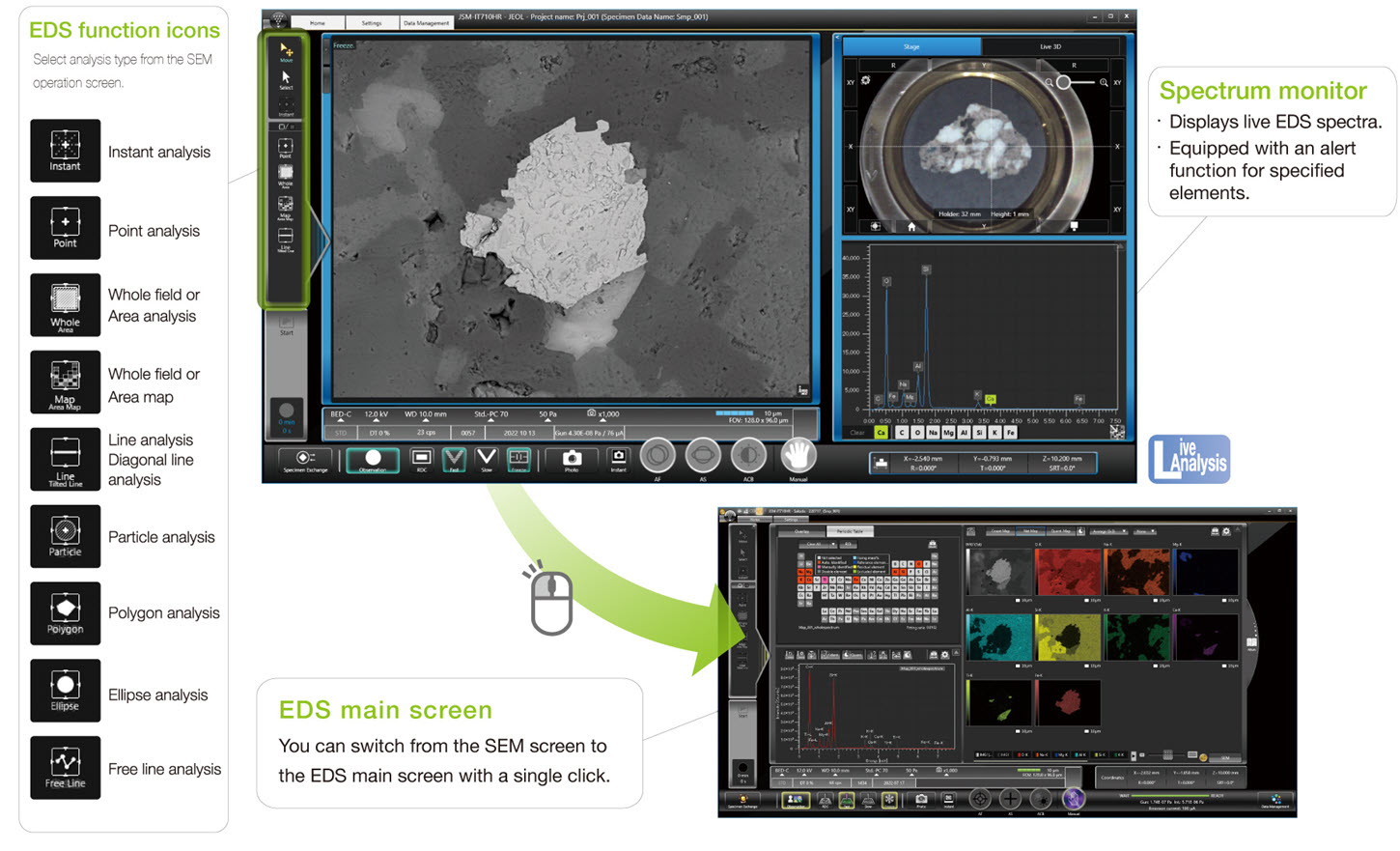

EDS Integration

JEOL manufactures and sells not only SEMs but also EDS.

Fully embedded EDS with SEM for simplified workflow, operation and data management.

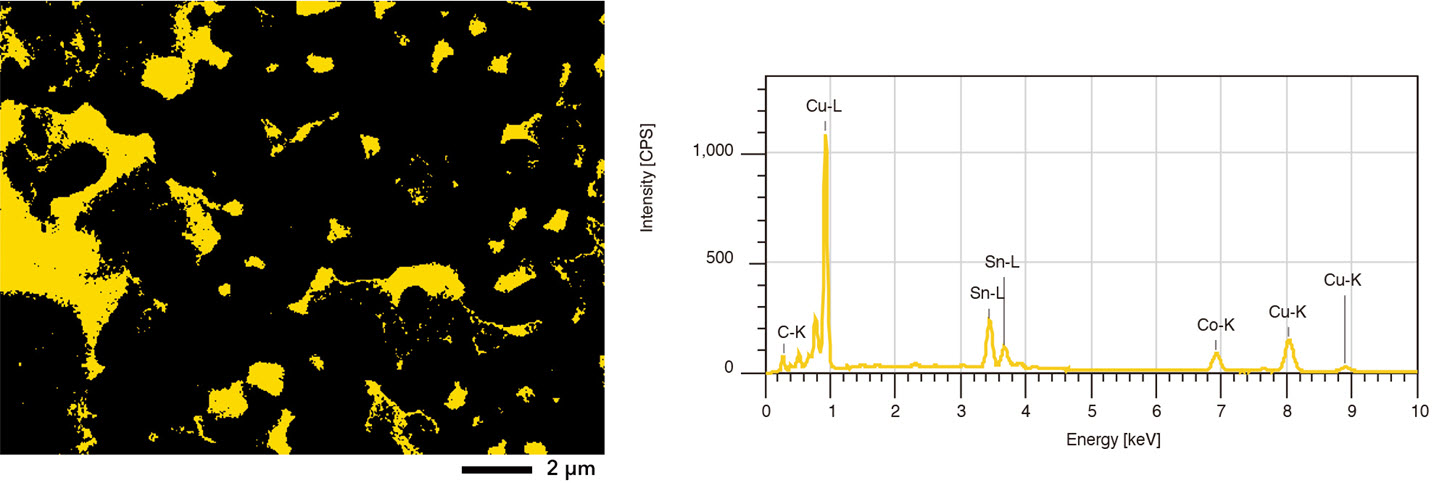

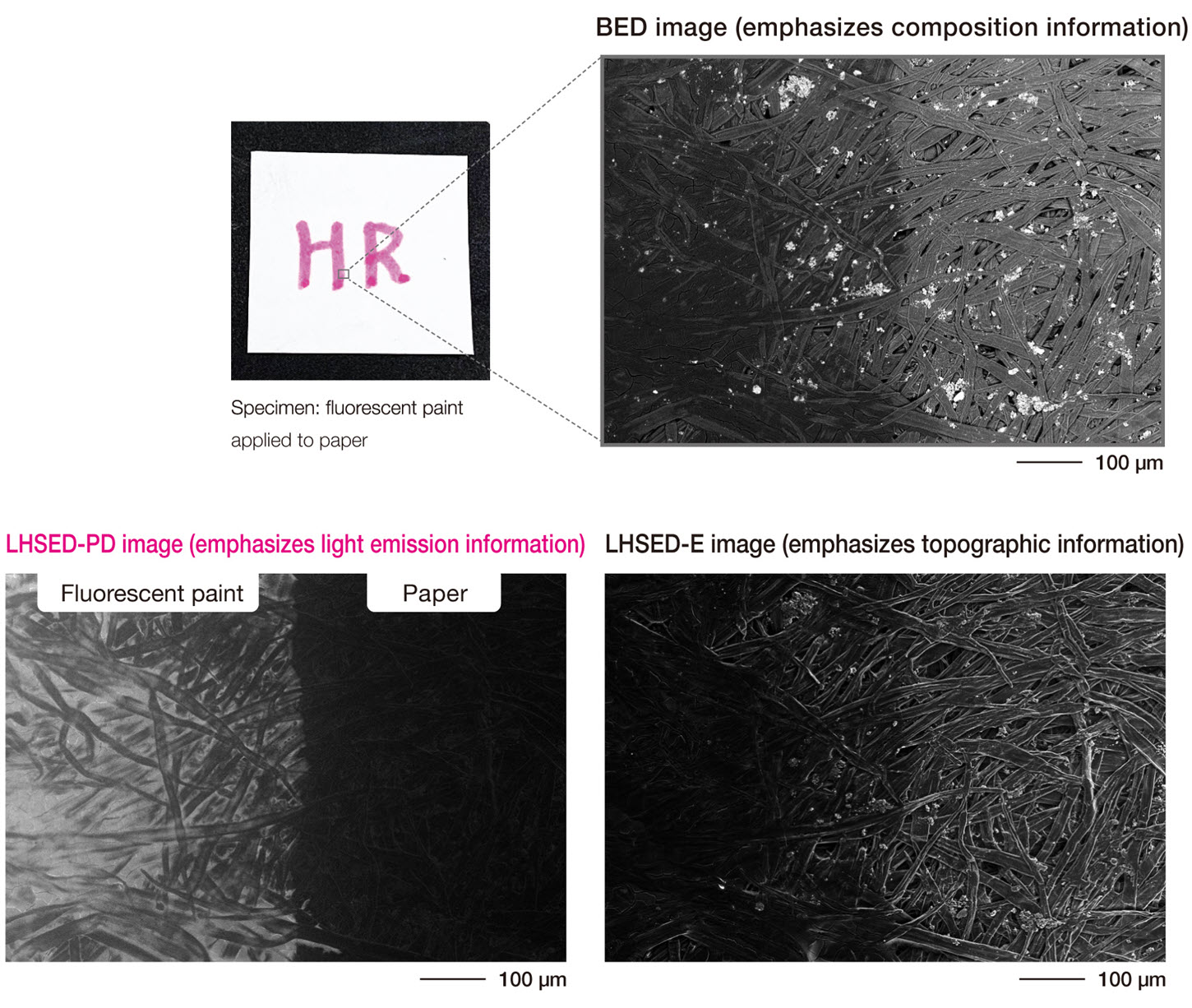

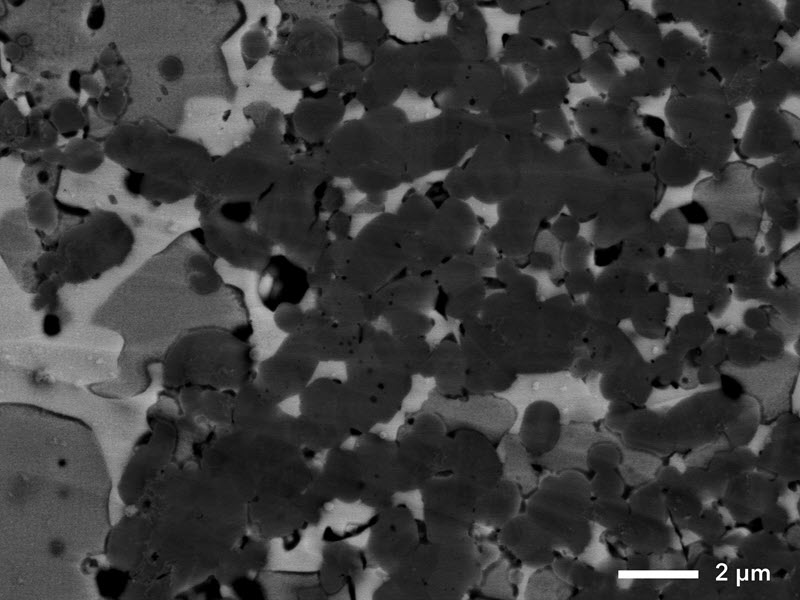

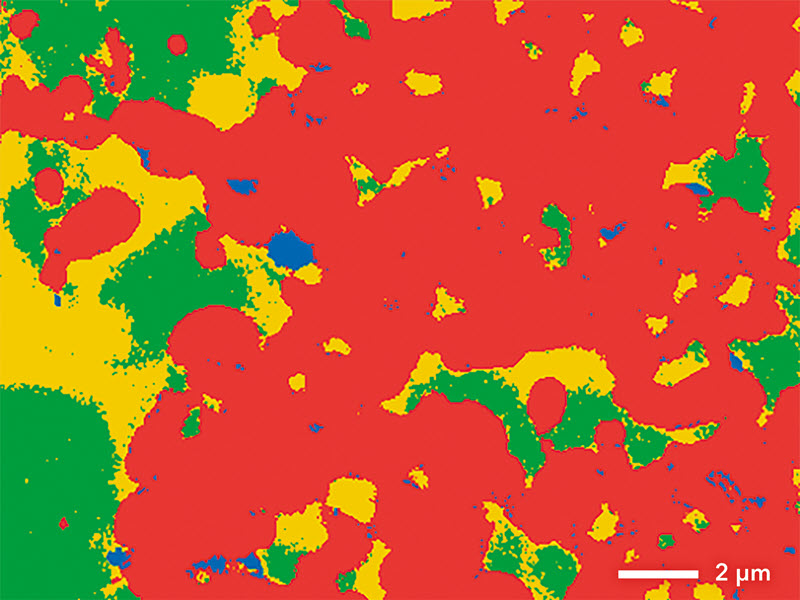

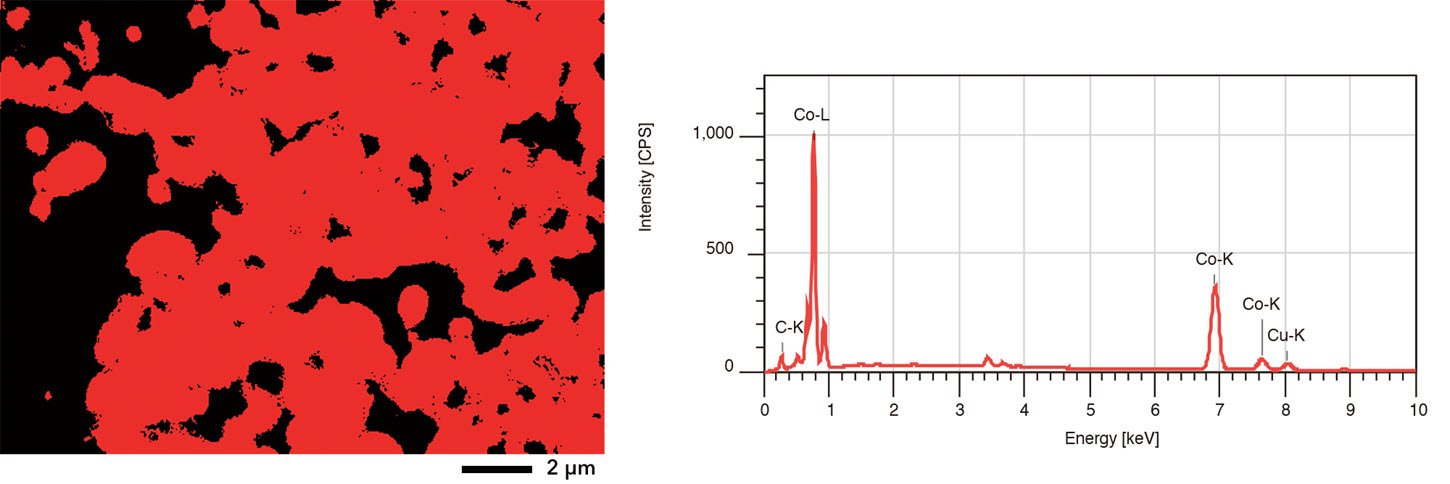

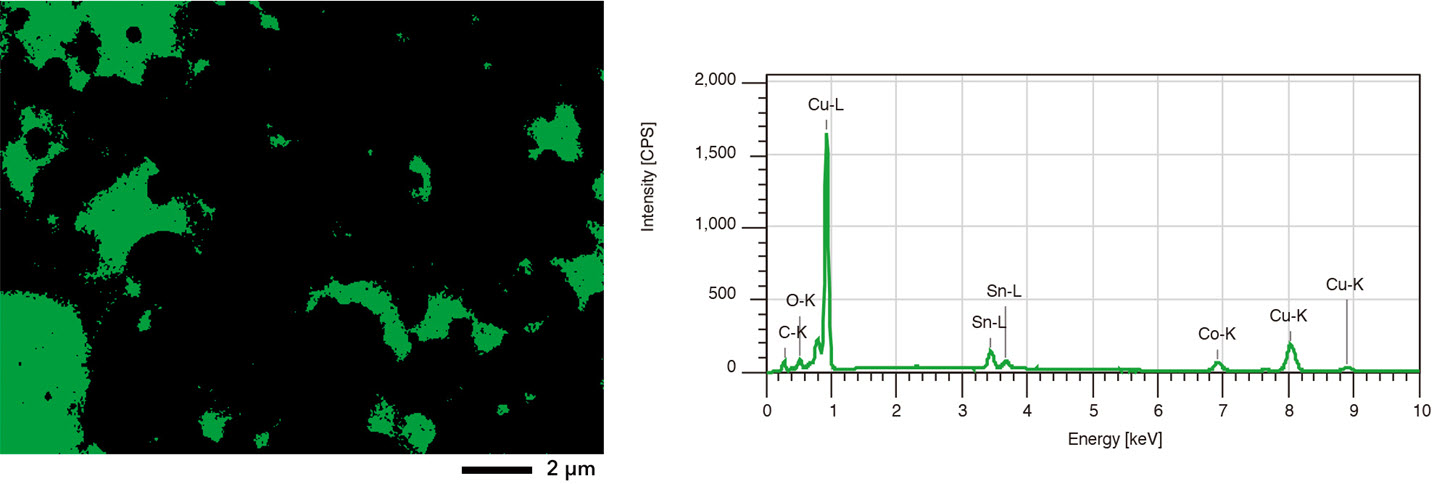

Phase Analysis

JEOL’s EDS system supports a new phase analysis function. Phase maps can be created from map data set.

Backscattered electron image

|

Phase mapping (Overlay of multiple phases)

|

| |

Specimen: cross section of a cutting tool for precision machining. Phase analysis indicates component difference between Co, Cu and Sn rich areas. |

Co area: 68.15%

CuSn (CuRich) area: 16.25%

CuSn (SnRich) area: 14.54%